Ebner aims to supply the engineering, process or plants of thermal process engineering especially in the field of viscose fibre. Ever since established in 1965,Ebner always attaches importance to developing its technology and keeps good relationship with clients all over the world. Business cooperation between Ebner and Nantong Sunshine Graphite Equipment Technology Co., Ltd will provide advanced and high quality plants and apparatus at reasonable price for viscose fibre production corporations.

Simple process of viscose fibre production

When producing viscose fibre, the pulp-which is mainly cellulose-is dissolved in caustic soda and subsequently precipitated under controlled conditions. The most important process worldwide is the so-called 'viscose process' where the alkaline pulp is treated with carbon disulfide (CS2) and dissolved by adding sodium hydroxide solution. A viscose orange-brown solution called 'viscose' is formed which is ripened, degassed and then pressed through spinnerets into a highly acidic spinning bath mainly composed of Na2SO4,H2SO4,ZnSO4.Here the cellulose precipitates in the process of so-called regeneration when CS2 and the by-product H2S is released.

Purpose of spinbath

The spinbath is a solution composed of Na2SO4,H2SO4,ZnSO4 and so on. The concentration of the solution depends on the type or kind of viscose fibre. During the viscose fibre production the spinbath is operated in circulation under consistent temperature and pressure. By-products generating from the production are recovered in treatment.

Equipment for recovering

In the common viscose fibre production there are some different processes which mainly depend on the production factory with different scale and equipments and water, steam and electricity supply.

Spinbath regeneration mainly comprises of such processes as degassing, evaporation and crystallization and so on.

Noxious gases such as H2S and CS2 rich in the spinbath solutions can be removed by degassing. Ebner can design different degassing plants meeting the customer's demands. There are many kinds of jet-pumps suitable for degassing plants.

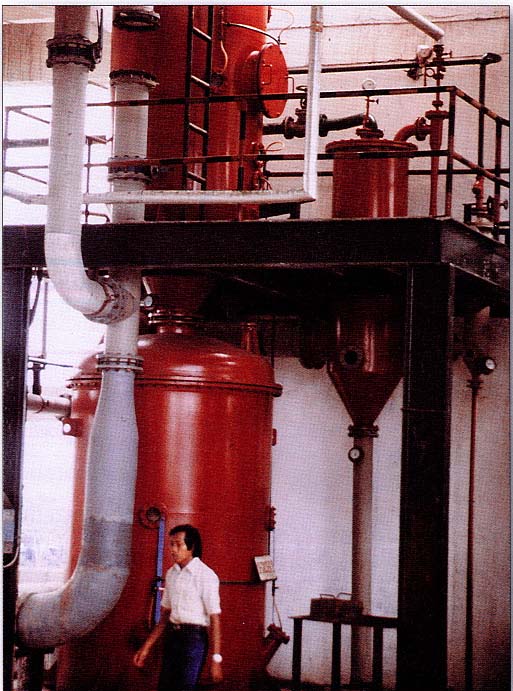

Evaporation plant

Evaporation plants are divided into circulation evaporation, flash evaporation etc. Ebner's flash evaporator is the most cost-effective one regarding the operating cost; this type of evaporator is suited for evaporation capabilities of more than about 5 t/h. Flash evaporator has a wide range of application in the interior market as its steam consumption low. Its characteristics including:

(1) high efficiency as the evaporation capabilities can be up to 10t/h.

(2) steam consumption is low that only 0.3 tons steam is consumed compared to generating each ton water.

Aside from the flash evaporation plants, Ebner developed the newest evaporator more efficient and economical recent years which are applied in foreign market.

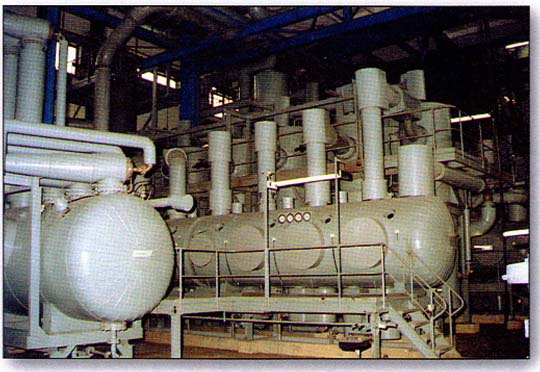

Crystallization plant

Plenty of Na2SO4 which yielded during chemical reaction is dissolved in the spinbath solution. The Na2SO4 should be removed through crystallization so that make a balance for the components of spinbath.

Continuous running vacuum crystallization plant of Ebner is mainly composed of condenser, crystallizer, storage tank and vacuum pumps. Water is vapored with the temperature decreasing at the same time plenty of heat is removed so that the crystalline will be produced. Vacuum crystallization is a perfect manner which is applied widely by many large companies.

4)焙烧设备

During crystallization a number of salts which precipitates contain crystal water, i.e. water molecules are included in their crystal system. These molecules have to be removed to allow further utilization of the salt.

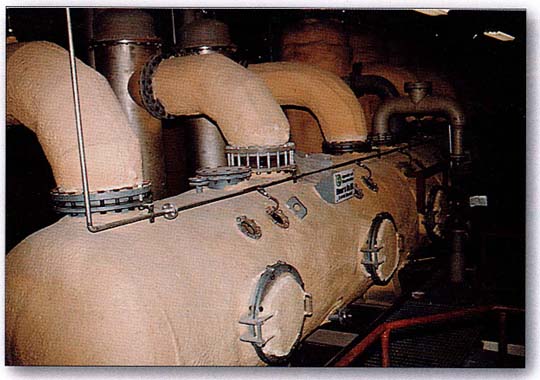

In addition to the conventional single-stages or multi-stages plants Ebner developed another type of plant to meet the economic requirements. By this development Ebner succeeded in minimizing the problem of incrustation in the heater tubes. the vapor which develops in the crystallizer may be utilized as waste steam with overpressure by other users.Self-cleaning heat exchangers

An alternative is the application of a self-cleaning heat exchanger. Ebner has the license of manufacturing the so-called self-cleaning fluidized bed heat exchanger, which was developed by the Technical University Aachen, and its sale all over the world. This makes it possible to reduce the incrustation to a minimum.